The Exploration Phase

The exploration techniques being deployed for this style of deposit are highlighted by low-cost and low environmental disturbance – shallow drilling.

Small samples are taken from each metre of the drill hole, the hole depths vary, anywhere from 4m to 18m to the targeted mineralised clay.

- Drilling stops when the limestone layer is reached.

- Drillholes are completed in less than an hour and backfilled immediately before moving on to the next location.

- The collected samples are then taken to AR3s warehouse in Naracoorte for preliminary analysis, before being transported to Adelaide for further more detailed analysis.

The Definition Phase

Part of Australian Rare Earths (AR3s) purpose is to unlock the rare earth materials, critical to producing cleaner and more affordable energy technologies, to provide a more sustainable future.

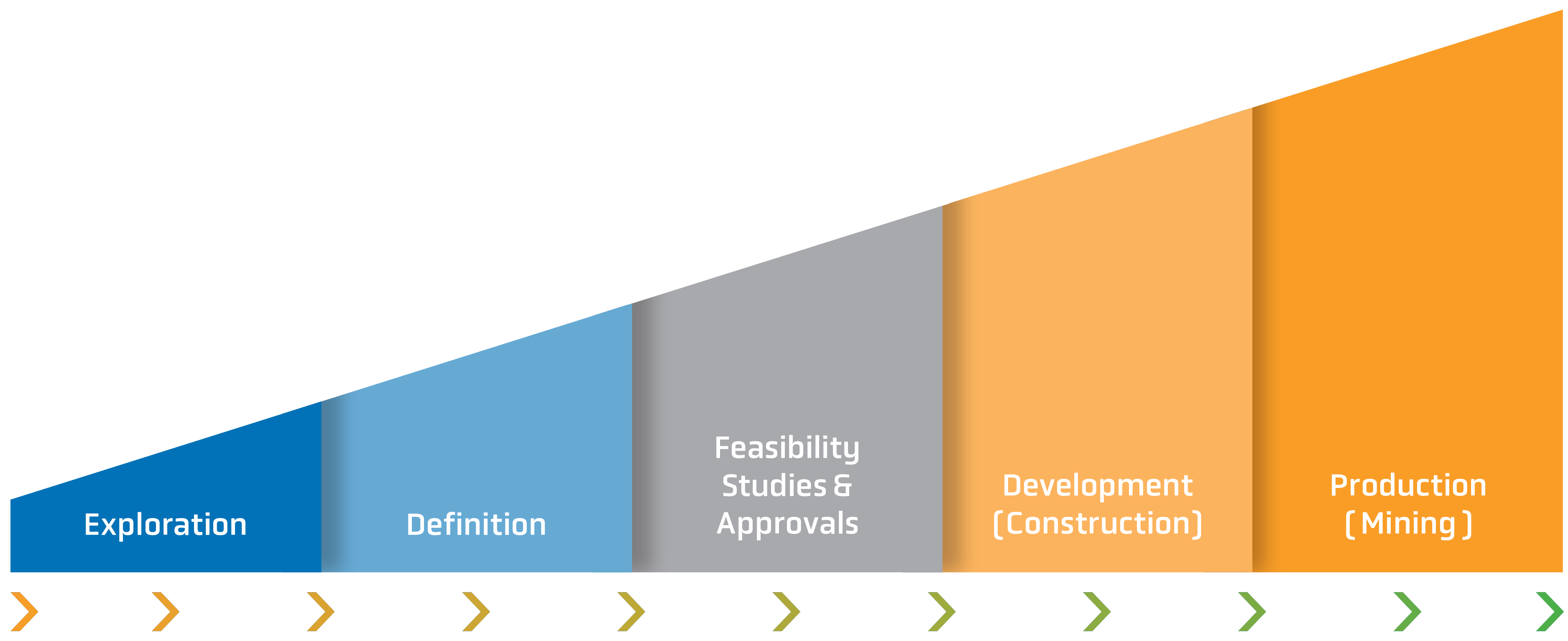

For a mineral company to progress from the exploration phase to the development phase of their project, the JORC resource needs to be better defined and eventually upgraded into a proven reserve. This is called the definition phase.

AR3 currently have Exploration Licences which permit exploration activities, prior to applying for a Production Licence to enable AR3 to produce (mine) rare earths on an economic scale, the South Australian, Department for Energy and Mining require AR3 to demonstrate that they can comply with strict regulatory requirements.

Australian Rare Earths have finished work on a trial pit to further their understanding of the resource. It will provide further information to enable AR3 to demonstrate to the Community and the Regulator exactly how they will comply with the strict regulatory requirements of The Mining Act 1971 (SA) and associated Mining Regulations 2020 (SA).

Definition phase

Koppamurra Trial Pit

Until now AR3s exploration activities have been focused on mapping and understanding the geology of the soils in the Koppamurra area, in terms of rare earth content, gaining an understanding of those areas that are rich in the much sought-after elements.

The exploration project has progressed to the definition stage, where AR3 are keen to understand how the rare earth elements will be extracted from the clay, and which of the multiple processing options will be the best fit for Koppamurra.

To better understand and define the resource at Koppamurra, AR3 excavated a trial pit to collect bulk samples of ionic clay, for off-site tests.

The Trial Pit enabled AR3 to:

- understand if the resource, in the quantities discovered in Koppamurra, is an economically viable mining opportunity

- better understand the production processes required to liberate the rare earth elements from the clay.

The trial pit measured approx. 100m x 40m, 10,000 tonnes of earth was excavated of which 3000 tonnes was mineralised clay. AR3 removed approximately 500 tonnes of the mineralised clay as bulk samples, for processing and analysis elsewhere (there are currently no purpose-built facilities to conduct this research within the region).

The findings from the trial pit will inform AR3s forward plans for the Koppamurra project.

The information acquired from the Trial Pit has confirmed what we already know, that clay hosted rare earth mining:

- is shallow-excavation mining which has a much lower impact than many other forms of mineral mining, the trial pit was excavated to a depth of 8m,

- does not produce radioactive waste materials.

- can be conducted with a progressive rehabilitation process, this enables the rapid restoration of land to its former condition and agricultural use

The Trial Pit Bulk Samples will also give a more accurate understanding of the:

- quantities of rare earth elements to be produced

- processing techniques to be utilised, to liberate the rare earths from the clay

- size, scale and location of the required processing plant

- waste streams that will be produced as part of the processing operations and how they will be managed

- potential long and short term risks to the Environment and how those risks will be mitigated

- methodology and time frames for site rehabilitation